Welcome to Guilin HCM Machinery Official WebSite!

Release date: 2023-10-09 11:32:07

The vertical mill dust collection system has two different layout plans based on the performance of the dust collector, namely a two-stage dust collection system and a single-stage dust collection system. The two-stage dust collection system is generally used for cement raw material grinding, while the single-stage dust collection system is generally used for dust collection on pulverized coal equipment in the cement and metallurgical industries.

HLM vertical mill system consists of main machine, feeder, classifier, blower, pipeline device, storage hopper, electronic control system, dust collection system, etc.

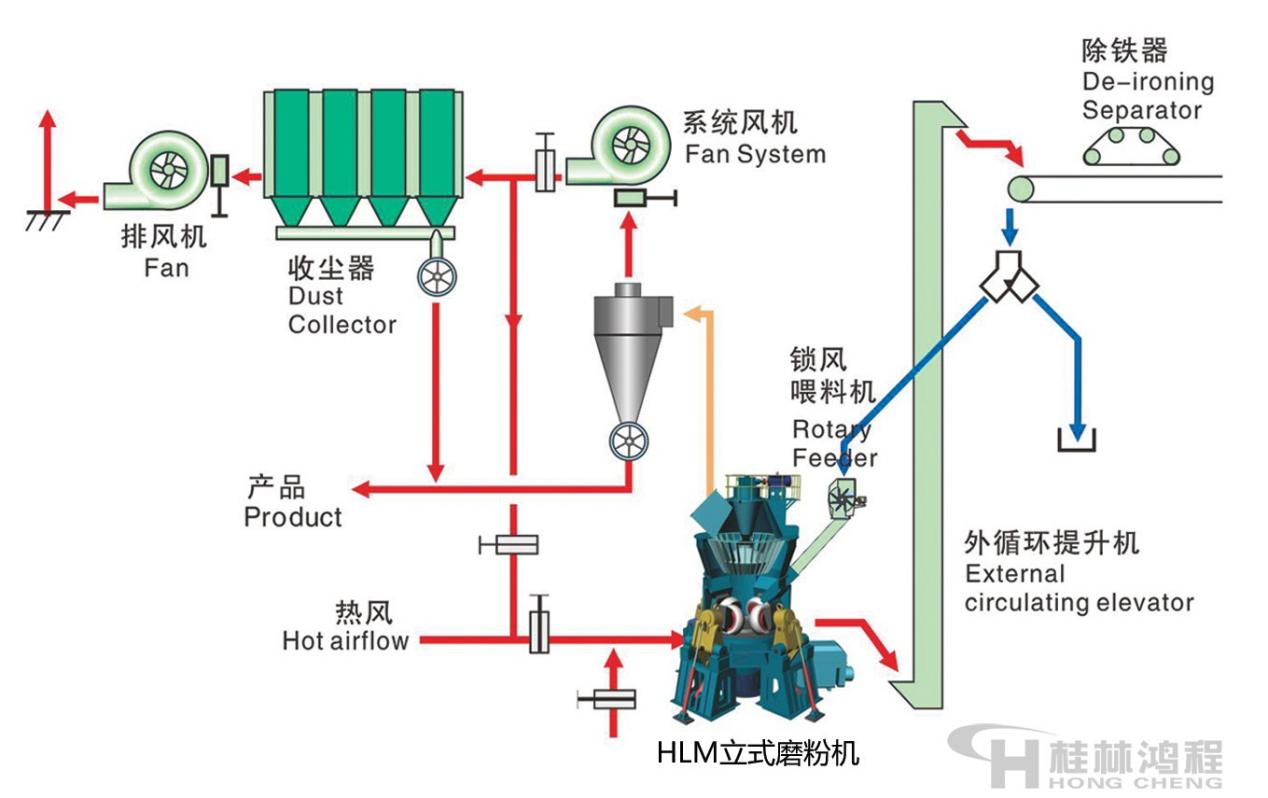

1. Vertical mill secondary dust collection system

The secondary dust collection system of the vertical mill uses a cyclone dust collector to collect products. This arrangement reduces the operating negative pressure of the system and the amount of gas passing through the dust collector. An electric precipitator or a pulse bag dust collector can be used as the final dust removal equipment.

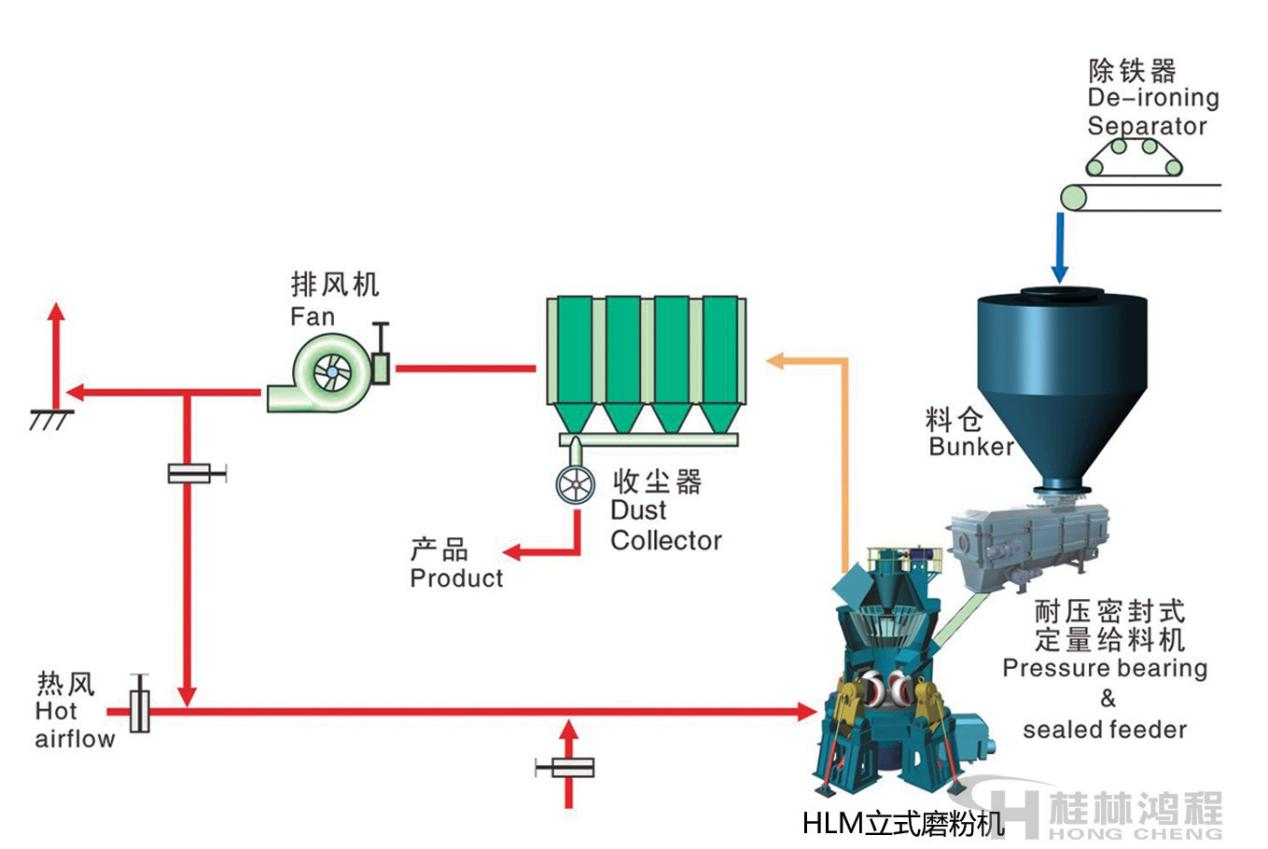

2. Vertical mill single-stage dust collection system

2. Vertical mill single-stage dust collection system

The dust collection device used in the vertical mill single-stage dust collection system is an explosion-proof bag dust collector, and the grinding gas directly enters the dust collector. This system reduces the number of equipment and simplifies system configuration.

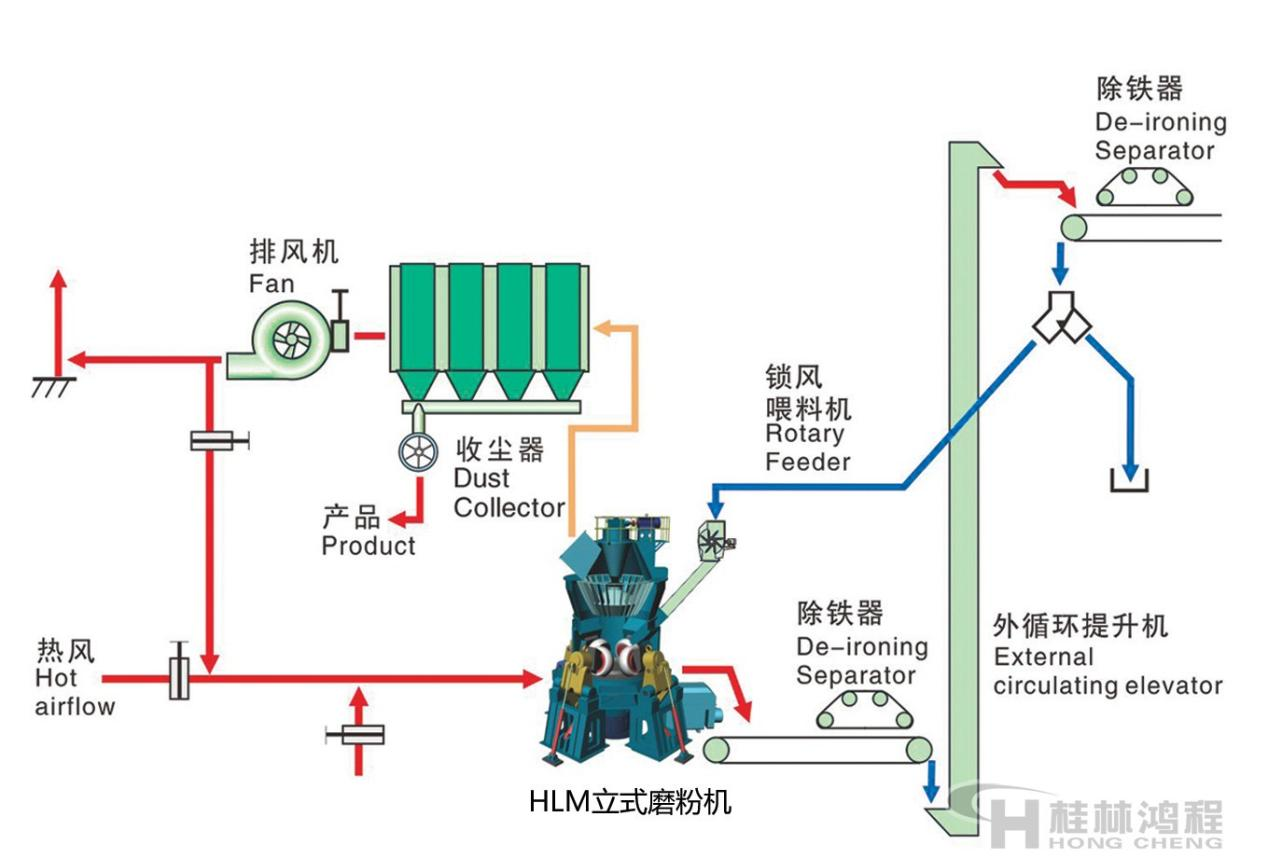

3. Single-stage dust collection system

Single-stage dust collection system is generally used in grinding equipment for grinding cement clinker, slag, steel slag, non-metallic ores, etc.

The dust collection device used can be a high concentration electric dust collector or a pulse bag dust collector.

HCM(Guilin Hongcheng) Vertical Mill has the following 8 major advantages:

HCM(Guilin Hongcheng) Vertical Mill has the following 8 major advantages:

1. Low comprehensive investment cost

It integrates crushing, drying, grinding, grading and transportation. It has a simple process flow, less system equipment, compact structural layout, and a small floor area, only 50% of that of a ball mill. It can be arranged in the open air, and the construction cost is low, which directly reduces the investment cost of the enterprise.

2. High grinding efficiency

(1) High grinding efficiency and low energy consumption. Compared with ball mills, energy consumption is 40%-50% lower;

(2) A single machine has a large production capacity and can utilize low-peak electricity;

3. Easy maintenance and low operating cost

(1) The grinding roller can be turned out of the machine with a hydraulic device. There is a large space for replacing the roller sleeve lining and mill maintenance, making maintenance operations very convenient;

(2) The grinding roller sleeve can be turned over for use, extending the service life of the wear-resistant material;

(3) There is no need to put cloth on the grinding plate before starting up, and the mill can be started without load, eliminating the trouble of difficult startup;

(4) Low wear, the grinding roller and grinding disc lining are made of special materials and have a long service life;

4. Product quality is stable

(1) The material stays in the mill for a short time, making it easy to detect the product particle size distribution and chemical composition, reducing repeated grinding and ensuring stable product quality;

(2) The product has uniform particle shape, narrow particle size distribution, good fluidity, and strong product adaptability;

(3) The product contains very little iron, and the iron contained in it is easily removed by mechanical wear. When used to grind white or transparent materials, the whiteness and purity of the product are high.

5. High reliability

(1) Use the grinding roller limit device to avoid severe vibrations caused by material interruption during the working hours of the mill.

(2) The new grinding roller sealing device is adopted, the sealing is more reliable, and no sealing fan is needed, further reducing the oxygen content in the grinding mill, and the explosion suppression performance is even better.

6. Environmental protection

(1) The entire system of HLM vertical mill has small vibration and low noise;

(2) The system is fully sealed, operates under full negative pressure, and has no dust spillage, making it basically possible to achieve a dust-free workshop;

(3) Vertical mill technology and equipment is a new energy-saving and consumption-reducing technology strongly advocated by the country, which is conducive to improving the competitiveness of enterprises in the region and even the national powder industry;

(4) Dust collection can use single-stage dust collection or two-stage dust collection. The dust collector is designed to use electrostatic precipitators such as pulse bag dust collectors, and the dust collection efficiency is as high as 99.999%.

7. High degree of automation

It adopts PLC fully automatic control system and can realize remote control, which is easy to operate and maintain, and reduces labor costs.

8. Strong drying ability

Since the vertical mill can directly vent hot air, the hot air directly contacts the materials in the mill, and the drying capacity is strong, and the moisture content of the feed material can reach 15%. The vertical mill pulverizing system does not need to be equipped with an additional dryer, saving equipment investment costs and energy consumption costs. By adjusting the temperature of the hot air, materials with different humidity can be dried and ground at the same time.

As a well-known domestic grinding equipment supplier, HCM(Guilin Hongcheng) produces various types of grinding machinery on the market. It configures different dust collection systems according to material fineness and output requirements, and provides a complete set of grinding production line configuration solutions. EPC general contracting is efficient and fast, build factories, install and put them into production for customers, and tailor-made exclusive grinding production lines.